Laser Welding / Laser Cutting

Laser welding / laser cutting

Both laser welding and laser cutting are modern technologies that are becoming increasingly common in industrial production. Both processes use focused laser beams to precisely process materials. With laser welding, robust and durable connections can be created between different materials thanks to high-quality weld seams. In contrast, laser cutting enables extremely fine and detailed cuts for complex shapes and designs.

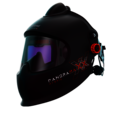

The main advantages of both processes are as follows: high speed and exceptional precision when working, as well as less deformation or material damage thanks to the low heat input. At the same time, the high-energy laser beam poses a considerable risk, especially to the eyes, but also to the skin and breathing. This makes suitable personal protective equipment (PPE) all the more important.