roboview

Patented anti-glare window for automated welding systems

Unrestricted view of the action

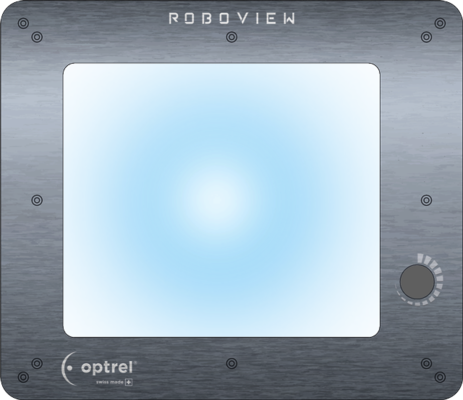

Automated welding systems must also be checked and checked regularly. Ideally, this process control is carried out during and after welding. The roboview anti-glare window now makes exactly this possible. A darkened view during the welding process and a clear view before or after welding. This allows the arc to be optimally observed during welding. Thanks to the stepless controller, the brightness can be changed as desired.

When the robot is not welding, the roboview offers a clear view of the robot cell and the weld seam. This happens automatically because the roboview with the welding robot or the controller is coupled. This ensures that the anti-glare window is always darkened when the robot is welding. Thanks to a field of view measuring 28 x 24 cm, the roboview offers an unrestricted view of what is happening and thus enables excellent monitoring of the welding process at all times.

Application

The roboview privacy window is active glare protection for installation in automated welding systems. The darkening is activated by activation of the robot controller or PLC without the disadvantages of optical arc detection. The light transmission can be continuously adjusted using the rotary knob. This privacy window is suitable for monitoring the planned processes in a welding cell. The integrated UV/IR filter reliably protects the user from dangerous radiation. This privacy window is not personal protective equipment (PPE) within the meaning of EU Directive 2016/425.

Technical specifications

item number

5050.000

Product description

Viewing window with darkening function for use in automated welding and cutting. Setting the protection level with a rotary knob. Control of the blackout by the robot or PLC.

window size

Field of view: 280mm x 240mm

Cutout for installation: 358mm x 302mm

control

24VDC High active, 10mA max.

0VDC - 4VDC = light level

12 VDC - 30VDC = dark level

protection level setting

Infinitely variable with a rotary knob

light transmission

Light level - Protection level 3

Dark level - Protection level 3-12

Ultraviolet-/Infrared protection - maximum in the entire protection level range

materials frame

Stainless steel

operating temperatur

-10°C to +55°C / +14°F to +131°F

areas of application

All electrical welding processes

Not suitable for laser welding!

scope of delivery

Viewing window including front panes, fastening material, operating instructions

Labelling

CE

standards

ISO 25980:2014-10, EU 2014/30/EU, EN 61000-6-2:2019-11, EN 61000-6-2:2005/AC:2005, EN 61000-6-4:2020-09

EN 61000 -6-4/A1:2020-09

warranty

From the date of purchase: 2 years for manufacturing and material defects